FEA is a powerful tool if used properly but developing in-house expertise is expensive.

Stress & Stiffness Analysis (FEA)

Applied Kinetics has a wealth of talent and experience with stress and deflection FEA analysis. We use an efficient balance of conventional engineering calculation techniques and FEA software tools to produce reliable results within your budget.

Whether your project requires FEA analysis of a single component, or a complex assembly,Applied Kinetics has the experience to produce reliable results.

Capabilities:

Applied Kinetics uses the most up-to-date software as part of its analysis solution. We maintain licenses in the full suite of available tools which gives us the ability to:

• Analyze a single part in extreme detail or large assemblies together.

• Perform automatic design iterations to optimize one or more design attributes

• Simulate drop tests

• Simulate vibrations and investigate harmonic frequencies of parts or structures

• Structural analysis can include both classic and bucking simulations.

• Long and slender objects can use long aspect ratio beam elements. This not only simplifies the model but also allows exceptional accuracy where traditional methods would produce poor results.

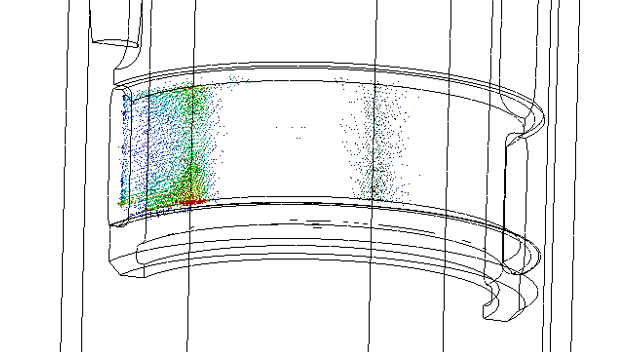

• We use a variety of meshing algorithms and carefully choose mesh dimensions to give you the most accurate results without unnecessary computational overhead.

• Multiple fastened, welded or bonded parts are a routine part of our analysis. We are capable, and have experience with, analyzing the stress and stiffness interaction between components made of multiple materials with vastly different properties (applications include metal inserts in plastic molds)

• We can integrate transient or static thermodynamic, stress, and cyclic fatigue loads into a single analysis.

Capability is only half the story...

Experience is the single most important analysis tool. Improperly simplified models, careless application of loads and poor choice of boundary conditions can easily change the output of an analysis by 50%. A full understanding of the application and failure modes, as well as having more than just an 'appreciation' of the mechanisms a FEA program uses, are vital to obtaining a valid a solution.

With todays software tool it is possible to simply mesh a model and complete the analysis, and for simple shapes this is often adequate. 9 times out of 10 the solid model must be edited and refined to be sufficient for analysis. Most of the analyses that Applied Kinetics performs require an indepth massaging of the element type and size in key areas to ensure proper aspect ratios and realistic stress or thermal transitions.

Our engineers are well trained and are continually tackling new analysis challenges. Our experience ranges from simple machine design related component verification to full mechanism certification reports. From the manufacturing industry to high performance aerospace we have the right combination of tools and experience to suit your needs.

Does your analysis company do all of this? Or do they just take the shortest path and deliver you whatever the computer tells them? At Applied Kinetics we believe that if a project is important enough to warrant a full anaylsis it is worth doing it properly.