A two stage project that involved optimizing the current process and then designing upgrades to reach performance targets.

|

Summary: After studying this highly dynamic steam system in the nuclear testing industry Applied Kinetics recommended improvements to optimize the process to get more out of the current set-up. The second stage was to analyze the system more thoroughly and determine what upgrades were necessary to meet new benchmarks for peak temperature and temperature ramp rates. |

||||||||

|

Details:

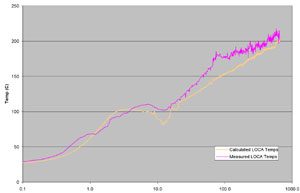

Steam systems are notoriously difficult to optimize. The combination of slow-to-react boilers, high power super-heaters, piping and other thermal losses, and process unknowns made this client's steam loop especially tricky. Even more challenging: our client was particularily interested in the transient response of the system. Since this system is used to test components for the Nuclear industry, the transient response can not be left up to chance and must be tightly controlled. As is often the case, the first step was to gather as much information (including test data) to establish a "current state". An empirical model was developed and matched to the data. The image below shows the correlation between the model and the test data. |

||||||||

|

Pink - Actual Data, Orange - Model Performance |

||||||||

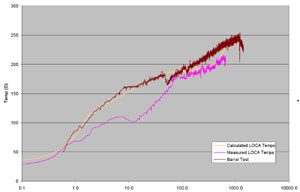

| The next step was to use this model to rapidly test hypotheses on how to increase the performance of the system. The image below shows the predicted system performance of the optimized process, the original performance, and test data for the optimized performance. | ||||||||

|

Prediced versus actual performance: Pink - Unoptimized System Test Data, Orange - Model Prediction for Optimize Process, Red - Actual Optimized System Performance. |

||||||||

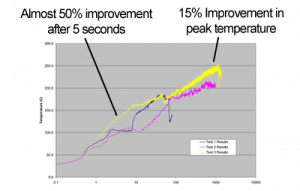

| At the end of this phase, significant improvements had been made using only process changes, no added equipment was necessary. | ||||||||

Transient System Performance Comparison: Blue and Pink - Before Optimization, Yellow After Optimization |

||||||||

| Applied Kinetics was able to use the same model in order to make targeted system upgrade recommendations with a high degree of confidence, avoiding the "shotgun" approach that is often used in the steam industry. In order to expedite approval, all of the upgrades were in compliance with TSSA guidelines.

|

||||||||