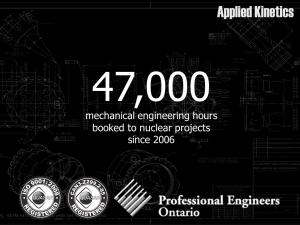

Nuclear customers have made up a significant portion of Applied Kinetics' engineering work since our inception.

|

|

| Nuclear customers have made up a significant portion of Applied Kinetics' engineering work since our inception. In fact, one of our first projects was for a nuclear client! Since 2006 we have booked more than 47,000 mechanical engineering hours to nuclear projects creating 5,600 manufacturing and assembly drawings as well as 3,000 engineering project and quality documents!

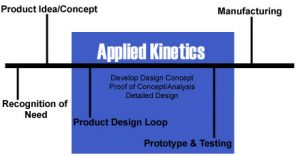

We have experience at helping our customers through every part of the project from sales to deployment. |

|

|

Key Factors that Drive Nuclear Designs:Foreign Materials Exclusion (FME) FMEA ALARA Code Compliance Outage schedule Materials selection Human Factors |

Our expertise in Nuclear combines our greatest strengths: mechanical design/concepting, project management, material engineering, and a phenominal attention to detail. Our expertise and experience are particularly applicable to:

|

|